Introduction

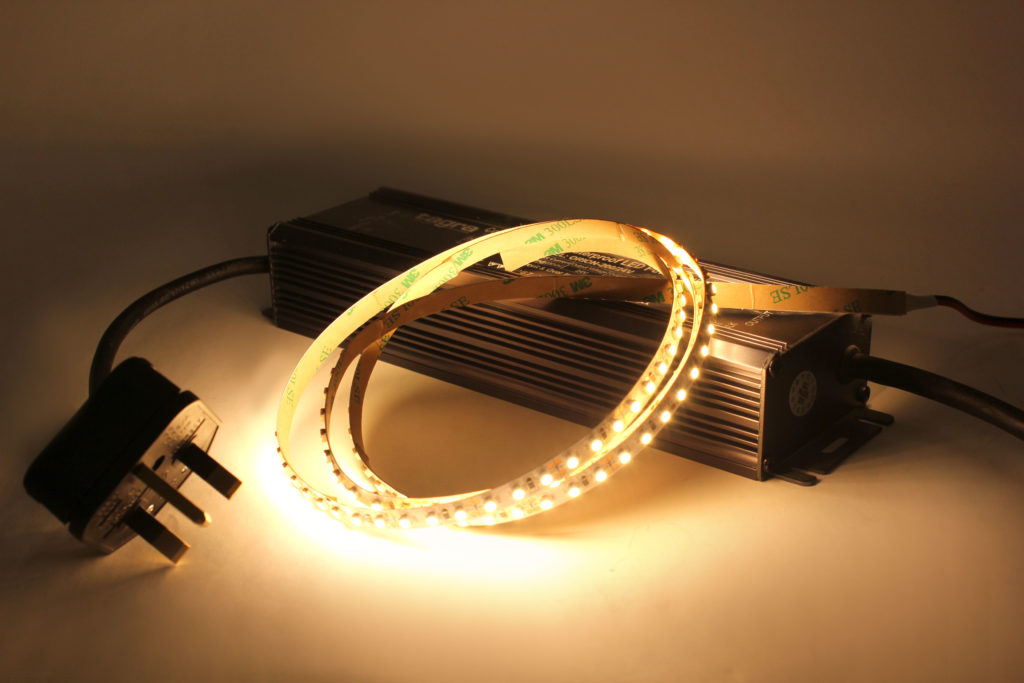

LED (Light Emitting Diode) lighting technology has become a dominant trend in modern lighting due to its high efficiency, long lifespan, and environmental friendliness. However, achieving high-quality LED lighting requires careful selection and quality control of LED power supplies. This article will explore the key parameter selection and quality control measures for custom LED power supplies to ensure the performance, reliability, and safety of LED lighting systems.

- Key Parameter Selection

1.1 Output Voltage and Current Stability

The primary objective of custom LED power supplies is to provide stable output voltage and current, ensuring consistent brightness and long lifespan for LED fixtures. When selecting output voltage and current, it is essential to consider the electrical characteristics and operational requirements of the LEDs. Typically, output voltage ranges from 12V to 48V, while current is determined based on the specifications and quantity of LED chips. Precise output voltage and current control circuits are critical to maintaining stability.

1.2 Efficiency

Efficiency of LED power supplies is crucial for energy utilization. Higher efficiency not only reduces energy wastage but also minimizes heat generation, extending the lifespan of LED fixtures and lowering energy costs. Generally, high-efficiency LED power supplies achieve an efficiency of over 85%, which requires optimization in the power supply’s topology and component selection.

1.3 Input Voltage Range

Considering different voltage standards worldwide, custom LED power supplies should be designed to adapt to various voltage ranges, typically between 110V and 240V. This can be achieved through multi-voltage input designs or adaptive power supply designs to ensure stable operation under varying voltage conditions.

1.4 Power Factor (PF)

Power factor is a parameter that reflects the power supply’s ability to convert electrical energy into useful power. Higher power factors typically indicate higher energy utilization efficiency, reducing the waste of reactive power. Proper power factor design helps reduce the electrical grid load and enhances grid stability.

- Quality Control

2.1 Protection Features

To ensure the safety and reliability of LED lighting systems, LED power supplies need to incorporate multiple protection features, including overcurrent protection, overvoltage protection, short-circuit protection, and over-temperature protection. These protection mechanisms prevent damage to LED fixtures in the event of power supply anomalies, ensuring user and equipment safety.

2.2 Electromagnetic Compatibility (EMC)

Electromagnetic compatibility is crucial to prevent power supplies from causing electromagnetic interference to surrounding devices and environments. Non-compliant EMC can lead to communication interference or equipment malfunction. Therefore, EMC considerations should be integrated into LED power supply design, with appropriate suppression measures.

2.3 Heat Management

Effective heat management is essential for the lifespan and performance of LED power supplies. Power supplies should be designed for efficient heat dissipation to prevent overheating-related failures. Heat dissipation designs may include heat sinks, fans, and temperature sensors to maintain stable temperatures, even under high loads.

2.4 Quality Control and Reliability

Establishing strict quality control processes is essential in manufacturing custom LED power supplies. This includes material inspections, production process controls, and final product testing. Reliability testing, such as lifespan testing and environmental adaptability testing, is also necessary to verify product performance and lifespan under different environmental conditions.

2.5 Safety Certifications

To ensure product safety and compliance, LED power supplies should undergo relevant safety certifications, such as UL, CE, and others. These certifications provide assurance to users and markets regarding the quality and safety of the products.

- Cost Control

When customizing LED power supplies, it is important to balance product performance and cost. Effective design and material selection can help reduce production costs while maintaining high performance and quality.

Conclusion

The parameter selection and quality control of custom LED power supplies are critical factors in ensuring the performance, reliability, and safety of LED lighting systems. When selecting parameters, considerations should encompass output voltage, current, efficiency, and power factor to meet the requirements of LED fixtures. Quality control includes protection features, EMC, heat management, reliability testing, and safety certifications, addressing multiple aspects to ensure product quality and safety. Ultimately, cost control is also an important consideration, requiring a balance between high performance and cost-effectiveness. By comprehensively addressing these factors, high-quality custom LED power supplies can be designed and manufactured, contributing to the advancement of LED lighting technology.